History shows us that ethyl acetate has been around since the 18th century. Back then, chemists figured out how to mix acetic acid with ethanol, draw off water, and walk away with a clear, fruity-smelling liquid. In the early days, the process needed sulfuric acid and took patience, but it set the stage for more efficient industrial production methods. Over the years, as the chemical industry sharpened its skills, producers moved to continuous processes with better safety, higher yields, and fewer leftovers. As demand for solvents grew through the 20th century, factories on both sides of the Atlantic started manufacturing ethyl acetate by the tankload, and the molecule became a staple in paint shops, labs, and food processing plants. The story of ethyl acetate is wrapped up in the bigger tale of global chemistry, from dusty benches in early European labs to busy refineries working round the clock today.

Ethyl acetate isn’t some mystery potion hiding in a lab cabinet. It appears in nail polish removers, printing inks, and even as part of the flavor profile in certain wines. Its sweet, fruity scent makes it easy to spot in a lab. Modern industry takes full advantage of its quick evaporation and decent solvency. Every year, millions of tons move through ports and down rail lines, destined for factories and workshops. Despite its flammability, its strong performance as a solvent and relative safety compared with tougher chemicals like toluene or benzene keep it at the center of a whole range of manufacturing sectors.

Ethyl acetate appears colorless and watery, but its boiling point of around 77°C makes it easy to separate from other liquids. The vapor travels quickly, carrying its sweet odor—one reason why this chemical pops up in everything from fruits to glue. Ethyl acetate dissolves well in most organic liquids, mixes with alcohol, and resists dissolving in water, although a bit of it finds its way into the mix. Anyone who’s ever left a lid loose on a bottle knows how quickly it disappears into the air, putting both flammability and environmental control at the top of the operational list. Its density runs lighter than water, so spills float, and this can help cleanup crews, but it also means extra safety measures in storage and handling.

Bottles and drums arriving at receiving docks list UN1173 for ethyl acetate. Technical sheets spell out a purity of 99.5% for industrial grades, with tough specs on water, acidity, and residue. Safety data sheets lean heavily on the risks—flash point sits low at -4°C, and the auto-ignition temperature hovers near 460°C. Labels demand hazard diamonds for flammable liquids and reminders about personal protective equipment. Weight, vapor pressure, and storage needs all trace back to careful trials and feedback from workplaces, setting a clear line between professional handling and casual use.

The most common factory method uses a reaction between ethanol and acetic acid, run in the presence of sulfuric acid as a catalyst. This process, called Fischer esterification, creates ethyl acetate plus water—so plants spend as much time controlling moisture as driving conversion. Some facilities turn to Tishchenko or acetoacetylation routes when feedstocks or regulations demand. Manufacturers value a process that recycles leftover ethanol back into the system, reduces waste, and wrinkles out what impurities might show up down the line. All told, a big petrochemical site can crank out hundreds of tons in a day, shipping it down the supply chain before most end users even realize a transformation has begun.

Ethyl acetate stands out for reacting in several useful ways. Chemists split it in two by hydrolyzing it, sending it back to acetic acid and ethanol, usually under acidic or basic conditions. In other reactions, it combines with amines, builds esters, or even serves as a launching pad for more complex molecules. Its relatively stable structure keeps it from falling apart in storage, but it still plays nice as a medium for reactions or as a carrier for pigments and additives. Many modifications adjust volatility or purity, and those feed improvements in both safety and flexibility for end users.

This compound pops up in catalogs as ethyl ethanoate, acetic ether, or even EA. Some folks call it “banana oil,” though that label sometimes wanders towards isoamyl acetate. Brands slap their own variations on drum labels, but the IUPAC and CAS numbers are hard to confuse. On the shelves of most labs, ethyl acetate takes its spot beside other basic solvents—a regular fixture for cleaning, extraction, and chromatography work.

Factories and labs deal with strict fire codes and occupational exposure limits. Handling ethyl acetate safely means using explosion-proof gear, vented hoods, and spark-proof tools. The vapor, if left unchecked, can cause lightheadedness, so workers keep monitor badges clipped on during larger jobs. EPA regulations cap air emissions, while OSHA spells out rules for airborne limits and emergency response. Training focuses on spill kits, eye protection, and the layout of emergency showers. Most manufacturing sites use tank sensors and regular fire drills to keep accidents down and provide quick response when the unexpected occurs. In transport, international shipping standards like IMO and ADR classify ethyl acetate as a flammable liquid, designating special procedures and clear placarding for every shipment rolling down the road.

The reach of ethyl acetate extends across the map. In coatings, it thins paints and lacquers, driving off rapidly for a smooth finish. Printers use it to dissolve dyes and inks, letting solvent-rich colors hit paper, plastic, or foil. The pharmaceutical industry leans on it for extracting active ingredients and as a reaction medium. Food companies, under tight regulation, use trace amounts for flavoring gum, candy, and baked goods. In labs, few things separate a mixture as cleanly as ethyl acetate during liquid-liquid extraction, and its compatibility with chromatography equipment keeps it in regular rotation among scientists. The leather and textile industries draw on it too, favoring its mix of strength and rapid drying for adhesives and surface treatments.

Chemists around the world study ways to cut energy use and carbon emissions during ethyl acetate production. Catalysts have jumped beyond traditional sulfuric acid to include zeolites and other solid acids that offer cleaner reactions and easier recycling. Some R&D projects experiment with fermenting biomass to generate ethyl acetate from renewable feedstocks, aiming at a product with lower environmental impact. In the applications space, research looks at tuning solubility and evaporation to meet new challenges in electronics or green chemistry. Many papers weigh the life cycle analysis of ethyl acetate-based processes, looking for places to trim waste or improve worker health.

Workers exposed to moderate concentrations of ethyl acetate may experience eye and respiratory irritation, but according to current studies, the body metabolizes it efficiently, breaking it down to less toxic compounds. Large-scale studies in animals point to low chronic toxicity, though prolonged exposure at high doses can depress the central nervous system. Regulators set workplace airborne levels well below those observed to cause harm. Research continues into environmental breakdown, with most studies showing that soil bacteria and natural processes break it down without lingering contamination, unlike heavier, halogenated solvents. Despite this, researchers push for improvements in fume control, spill containment, and routine health monitoring—especially in developing regions where regulations may lag.

The next decade will see more bio-based production and stronger focus on lifecycle sustainability. As industries switch to solvents with a lower environmental impact, demand for ethyl acetate made from renewable sources could surge. Technology firms chase super high-purity grades for delicate electronics, while green chemistry principles keep pressing for recyclable or less hazardous alternatives. Automation in plants, better leak detection, and tighter emission controls promise to both cut costs and curb risks. I see a future where ethyl acetate remains valuable—but used with a sharper focus on resource conservation and workplace safety. The march of innovation won’t slow down, and as new challenges emerge, this chemical will adapt and keep its place on the frontline of industry and research.

One whiff of nail polish remover or some perfumes quickly gives away the presence of ethyl acetate. In my time messing around with hobbyist resin crafts and DIY perfumes, I kept seeing this stuff pop up on ingredient lists. Chemists love it for its pleasant, fruity smell that doesn’t stick around too long. In the perfume industry, ethyl acetate acts as a solvent, helping blend other fragrance molecules. It evaporates quickly, letting the actual scent land on your skin instead of the chemical carrier. The same goes for nail polish—the solvent helps spread color, then it vanishes, leaving behind a glossy look. Without it, formulas get goopy or take way too long to dry.

Ethyl acetate helps printers and painters more than most folks realize. In printing inks, it keeps ink at a flowy consistency that glides across paper and then vanishes fast enough to avoid smudges. I remember volunteering for a community mural project and learning how much trouble you get when paint dries at the wrong speed. Too fast, and you can’t work the colors; too slow, and the details blur. Because ethyl acetate flashes off at just the right pace, manufacturers rely on it for quick-dry spray paints and industrial coatings. The film left behind doesn't get marred by fingerprints or dust falling on slow-drying surfaces. People appreciate the results, even if they’ve never heard the chemical’s name.

There’s a softer side to ethyl acetate: food processing. It pops up as a flavor enhancer in products like candies, baked goods, and even wines. It delivers a subtle fruity note that’s gentle on the palate. But there’s an even bigger story in coffee and tea. Many decaffeinated blends use ethyl acetate to pull caffeine from beans without wrecking their flavor. Food scientists prefer it for its low toxicity at the levels used. I’ve talked to baristas who say beans treated with ethyl acetate taste more “real” compared to super-intense industrial decaf methods. Yes, a little chemistry can keep afternoon jitters away without giving up on flavor.

Pharmaceutical labs run on solvents, and ethyl acetate finds a lot of friends here. It helps extract active ingredients from plant materials and mixes easily in synthesizing antibiotics or pain relievers. There’s less worry using ethyl acetate because it breaks down swiftly and leaves little behind. In my own high school chemistry classes, we cleaned glassware with it— because nothing cuts through sticky residue quite as neatly, and it rinses away with little fuss. Researchers keep a bottle handy for chromatography, separating things out in the lab for pure analysis. Reliable solvents like this go a long way to making new medicines safer and more affordable.

There’s a bright side to how ethyl acetate breaks down quickly in air and water, making it less likely to linger in places it shouldn’t be. The Occupational Safety and Health Administration sets exposure limits to keep workers safe. Over the past few decades, companies shifted away from nastier solvents, choosing ethyl acetate more often to cut risks in factories and workshops. Knowing what goes into everyday products helps us push for better labeling and safer alternatives. Engineers still hunt for greener choices, but for now, ethyl acetate’s mix of function and safety means it stays on the roster for many industries.

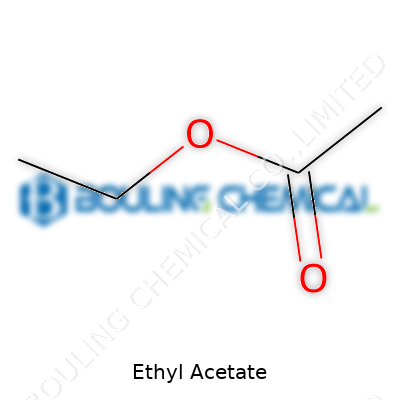

Ethyl acetate. Most folks spot it in things like nail polish remover or glues, breathing in its sharp, sweet smell. In the world of chemistry, this liquid goes by the formula C4H8O2. That little combination of carbon, hydrogen, and oxygen shows up much more than you might think, in factories, labs, even the food industry.

It’s tempting to think of formulas just as trivia you leave behind after your school days. Still, knowing that ethyl acetate is C4H8O2 makes a difference. This formula tells chemists exactly how many of each atom pile together to form this liquid. When you know the formula, you know what this substance might do, how safe—or unsafe—it is, and what reactions to expect if you mix it with something else.

I remember working a summer job in a small lab, with bottles that hardly said more than a name and a formula. No one held my hand through chemical safety. You had to respect the symbol on the label. Knowing the formula not only helped me recognize what I was using, it often kept me clear of nasty accidents. The chemical formula wasn’t just numbers; it was a shorthand for risk and responsibility.

Ethyl acetate has a way of finding its path into daily routines. Factories use it to make paints and coatings dry faster. Winemakers rely on it because it pops up naturally during fermentation, adding fruity notes. Food companies add measured amounts because it helps extract flavors.

There are health and environmental angles to think about with this formula. Ethyl acetate breaks down fast in air, so it does not hang around like heavy industrial chemicals. Exposure to high concentrations can cause headaches or sedation. You start to wonder about safety above all else. This makes labeling and chemical literacy crucial, especially when schools and homes get stocked with things containing this solvent.

Many stories floating around about chemicals make people nervous, even though they handle compounds like ethyl acetate regularly. Real trust starts with clear, straightforward information. Long before regulators put strict labels on bottles, my own family ran a printing business. The shop used cleaning solutions packed with solvents much like ethyl acetate—often they had no clear label. Over time, I saw the benefit in reading up, in staying alert, not just following a routine blindly.

If everyone learns how to read a formula like C4H8O2 on a product, it sets a higher bar for safety and public discussion. Being open about what’s in the air or on the shelves means fewer surprises and smarter choices. Fact sheets, better training, and digital resources could close the knowledge gap, so no one’s left guessing about what a formula stands for.

Good science starts with good information. Chemistry classrooms can move beyond rote memorization by teaching what each chemical formula suggests about safety and use. True, it’s easy to see numbers and letters and tune out, but making that knowledge practical saves lives and builds confidence. Digital apps, interactive labels, and hands-on demonstrations in shops and schools could bridge the gulf between experts and the public.

For anyone still wondering: ethyl acetate’s formula, C4H8O2, keeps showing up in ways big and small. Understanding it means real-world skill—one that helps people stay safe, ask smarter questions, and trust what’s in their hands.

Ethyl acetate shows up in more places than most people realize. I’ve smelled it in nail polish remover, cleaning up after painting, and even catching a whiff from some old bottled glue. Used as a solvent, it helps make coatings, inks, and cosmetics behave the way we expect. Scanning the ingredient list on common products brings ethyl acetate into focus, raising the question: should I really breathe this stuff in or touch it without a second thought?

The sweet, fruity odor might seem harmless. My eyes and nose felt irritated after spending a long afternoon cleaning up paint stains indoors, even in a well-ventilated room. The Centers for Disease Control and Prevention (CDC) and Occupational Safety and Health Administration (OSHA) point out that vapor can trigger headaches, dizziness, and nausea if levels go high enough. My own lightheadedness faded once I stepped into fresh air, but I wouldn’t push those effects aside as just “part of the job.”

Skin exposure tells its own story. I once knocked over a small bottle of nail polish remover onto my hand without gloves. The cool, tingling sensation quickly gave way to dryness and a mild burning. That lines up neatly with the warnings about repetitive contact leading to irritation and possible dermatitis. The signs aren’t subtle, and each time someone brushes off these symptoms, they risk a more severe reaction if they keep coming back to that exposure.

People working in manufacturing, laboratories, or art studios cross paths with ethyl acetate fumes far more often than someone using nail polish a few times a month. The U.S. National Institute for Occupational Safety and Health (NIOSH) sets the recommended exposure limit at 400 parts per million for an average work shift. Concentrations above that can cause real trouble—deep headaches, trouble breathing, and coordination problems in a busy factory or workshop. Over the years, safety sheets have piled up warning that chronic exposure may damage internal organs, even if the strongest links show up in animal testing more than in humans.

Advertising and product design often lull people into thinking that ingredients allowed in cosmetics or food must be harmless. I’ve seen friends shrug off the warning labels, believing that “if it’s sold openly, there’s nothing to worry about.” This trust sidesteps the critical point: just because ethyl acetate drops below a certain limit in nail polish or flavoring doesn’t give blanket approval for unprotected use or careless inhalation. Regulatory agencies set those limits for a reason. Meanwhile, these products move quickly from the shelf into households where parents, kids, and pets live daily life.

Recognizing the risks creates space for safer habits. The simple choice to run a fan or open a window in a small bathroom can keep fumes from building up. Glove use may feel excessive at first, but skin only needs a few exposures before it starts to suffer. Employers need to provide proper ventilation and frequent air checks, along with training for anyone handling strong solvents day after day. Awareness campaigns in schools or salons could hand people the tools and knowledge they need to avoid preventable harm.

I’ve learned to treat chemical labels as more than background noise. Ethyl acetate isn’t some mysterious compound locked in factories—overexposure can affect anyone, with effects ranging from mild irritation to serious headaches and, over time, worse outcomes. The chemical has real uses. Respecting its risks and handling it with common-sense safeguards creates fewer regrets in the end.

Ethyl acetate ranks among those chemicals that show up everywhere - in workshops, paint stores, pharma labs, and even food factories. People use it for cleaning, extracting, or making flavors and fragrances. It’s sharp and sweet-smelling, but what jumps out most is how quickly it evaporates. That swiftness makes it favored for fast-drying products, yet it means storage blunders can turn costly and dangerous in a hurry.

I remember working in a shop where a cracked drum got ignored for a day, and the whole place smelled like nail polish remover. Turns out, ethyl acetate vapors build fast in closed spaces. Mix those vapors with enough oxygen, add a spark from an old light switch, and you’re facing a fire. This isn’t just theoretical — the National Fire Protection Association (NFPA) classifies ethyl acetate as a Class IB flammable liquid. That puts its flash point well below room temperature.

Stashing it near an open flame or typical heaters feels reckless. Even static electricity can do the job if enough vapors collect. Unfortunately, some places cut corners, thinking, “It’s just solvent.” Forgetting the facts brings consequences. Insurance costs rise after even small fires, and health takes a hit when exposure happens over time.

Smart storage starts with the right container. Steel drums with tight, gasketed bungs work best for large batches. Smaller bottles should always be glass or high-grade plastic, clearly labeled with the date. I’ve seen makeshift setups with soda bottles or low-grade caps leak, and the stench alone gives away how much has escaped.

The right spot means a cool, shaded area with reliable ventilation. A good setup pulls fumes away from noses, never letting the smell linger. Stash the containers away from exits, electrical panels, and obvious heat sources. Flammable storage cabinets aren’t fancy showroom gear — they do their part during the sort of accidents that nobody expects until it’s too late.

Reading the Material Safety Data Sheet (MSDS) sounds tedious, but every person who moves or measures ethyl acetate should pick up the habit. In jobs I’ve held, the safest teams were always the ones who talked openly about recent spills, near-misses, and actual incidents. Panic only grows in the dark.

Regular checks spot container wear and aging. I watched one shop bring in barcode tracking for every drum and bottle, catching inventory problems before they led to ghost volumes and expired waste. Eyes on gauges and smell detectors keep conditions transparent. A single slip — like ignoring a rusty seal or hiding a split canister — can mess things up quickly.

Holding onto old solvents “for later” rarely ends well. Waste processors know the risks, taking leftovers to specialized treatment. I’ve seen well-meaning workers dump leftovers into generic bins — never a good idea with volatile solvents like this one. Floor drains, storm sewers, or dumpsters lead straight to trouble, sometimes legal, sometimes ecological.

Having simple spill kits in reach — absorbent pads, gloves, goggles — and a fire extinguisher marked for chemical use makes the difference. Fire department contacts shouldn’t live on a note taped to a back door; every team should know who to call, and fast.

Respect pays off. A clean, aired-out, organized storage space avoids hospital bills, ruined products, and regulatory headaches. Anyone who’s worked close to flammables learns fast: shortcuts return as damage and regret. Treat ethyl acetate with care and it stays a valuable tool instead of a hazard waiting to explode.

Ethyl acetate has a place in many industries. Workers know the sharp, sweet smell if they’ve spent any time in a lab, factory, or paint shop. Its uses look innocent enough—making nail polish remover, printing inks, or adhesives. The tricky part starts with how easily it evaporates and how fast it can catch fire. The vapors spread before you can see them, sneaking near a heat source and causing a flash fire. In tight spaces, one spark and the whole room can go up. There’s no warning, and no time for second thoughts.

This stuff hits harder when breathed in. In my own experience, headaches come fast after cleaning up with it for long hours, even with fans blowing. The symptoms sometimes feel like a heavy fog—nausea, sore throat, and your eyes sting all day. Even at lower concentrations, working unprepared turns a regular shift into a scramble to steady your balance or catch your breath. With repeated contact on skin, redness and cracking show up. Leaving off gloves to move quicker might seem tempting, but that shortcut leaves hands stained and itchy, even after scrubbing with soap.

Vapors from ethyl acetate don’t stay put. They move low to the ground, collecting in corners and pipes. What worries me most is how easy it is for those vapors to linger once a spill happens on a warm day. If nearby work crews ignore the haze, the chance of inhaling a big gulp rises. Even the strongest workers have ended up at the nurse’s office after thinking opening a window was enough.

Problems only get larger when storage gets ignored. Leaving cans open or storing them near acids causes reactions that might not show until the next shift. Labels fade, containers get mixed, and new hands picking up an unmarked jug think it’s water or another solvent. Accidental mixing has caused enough small explosions over the years to keep my coworkers on edge.

Strong ventilation makes the biggest difference. Forced air, pull-away fume hoods, and open doors keep the air from getting thick with vapors. Relying on natural airflow fools many; only machines can turn danger into just another workday. Fans alone don’t cut it in windowless rooms. In jobs I’ve worked, people respected the buddy system for a reason—a second set of eyes means someone else catches a pooling spill or faulty equipment.

Wearing gloves, chemical splash goggles, and flame-resistant coats strikes some as overkill. Folks get used to skipping steps, especially when routines get rushed. Reminding each other to put on eye protection and gloves should come from the work culture, not just posted rules. Immediate cleanup after spills, keeping absorbent materials in reach, and clear, clean labels protect everyone—new hires and old-timers alike.

Storing ethyl acetate away from heat, sparks, oxidizers, and acids is more than a checklist item. Dedicated cabinets save lives. Training isn’t a one-time video. It needs walk-throughs with real containers and mock spills. Fire extinguishers rated for chemicals, eye wash stations, and showers turn a close call into a minor incident instead of a disaster.

Hazards grow from routine and forgetfulness more than from bad luck. Solid training, good habits, and equipment placed within arm’s reach matter more than any written warning or label. Each worker stepping into a shop or lab can turn a risky chemical into just another tool, so long as the respect for its hazards becomes second nature.

| Names | |

| Preferred IUPAC name | Ethyl ethanoate |

| Other names |

Acetic ester

Ethyl ethanoate Acetic acid ethyl ester EtOAc |

| Pronunciation | /ˈiːθɪl ˈæsɪteɪt/ |

| Identifiers | |

| CAS Number | 141-78-6 |

| 3D model (JSmol) | `ETHYL ACETATE; JSmol 3D model string: CC(=O)OCC` |

| Beilstein Reference | 635379 |

| ChEBI | CHEBI:27750 |

| ChEMBL | CHEMBL107119 |

| ChemSpider | 6084 |

| DrugBank | DB03157 |

| ECHA InfoCard | 03b6b30b-c0be-4127-b8a9-5bc512c51057 |

| EC Number | 205-500-4 |

| Gmelin Reference | 10220 |

| KEGG | C01060 |

| MeSH | D020820 |

| PubChem CID | 8857 |

| RTECS number | AH3325000 |

| UNII | NFY6TTPB0S |

| UN number | 1173 |

| Properties | |

| Chemical formula | C4H8O2 |

| Molar mass | 88.11 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | fruity |

| Density | 0.897 g/cm³ |

| Solubility in water | 8.3 g/100 mL (20 °C) |

| log P | 0.73 |

| Vapor pressure | 73 mmHg (20°C) |

| Acidity (pKa) | pKa ≈ 25 |

| Basicity (pKb) | pKb = 15.5 |

| Magnetic susceptibility (χ) | '-45.8×10⁻⁶ cgs' |

| Refractive index (nD) | 1.370 |

| Viscosity | 0.45 mPa·s (at 25°C) |

| Dipole moment | 1.78 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 160.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | −483.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2221 kJ/mol |

| Pharmacology | |

| ATC code | V03AB05 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02, GHS07 |

| Signal word | Warning |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P264, P271, P280, P303+P361+P353, P305+P351+P338, P312, P337+P313, P370+P378, P403+P235, P501 |

| NFPA 704 (fire diamond) | 2-3-0 |

| Flash point | -4°C (25°F) |

| Autoignition temperature | 427 °C |

| Explosive limits | 2.2% - 11.5% |

| Lethal dose or concentration | LD50 oral rat 5,620 mg/kg |

| LD50 (median dose) | LD50 (median dose): 5,620 mg/kg (rat, oral) |

| NIOSH | KL5775000 |

| PEL (Permissible) | PEL: 400 ppm (1400 mg/m³) |

| REL (Recommended) | 400 ppm |

| IDLH (Immediate danger) | 2000 ppm |

| Related compounds | |

| Related compounds |

Acetic acid

Ethanol Methyl acetate Butyl acetate Propyl acetate |